The Instituto de Física de Cantabria (IFCA) carries out an intense research work. In parallel with this activity, it develops an important instruments design and development task as a response to the increasing and demanding scientific needs. In general, the majority of instruments used in the physics field are single-use prototypes. Each equipment requires an unrepeatable design and development. This entails an important technological potential.

The Instituto de Física de Cantabria (IFCA) carries out an intense research work. In parallel with this activity, it develops an important instruments design and development task as a response to the increasing and demanding scientific needs. In general, the majority of instruments used in the physics field are single-use prototypes. Each equipment requires an unrepeatable design and development. This entails an important technological potential.

This institution wants to open a communication channel between the research community, who provides scientific advances and results, and the companies who are able to employ the solutions and discovering to the needs or to the development of new products and services. This is addressed not only to the companies interested in the development of astrophysics and high energies instruments but also to all scientific, technological and industrial disciplines which can be benefited from the knowledge and means of IFCA .

In this section the technological strengths and capacities that are currently being developed in our center, as a result of intense scientific effort, and its main means and facilities are introduced.

Since 2008, the laboratory has ISO 9001 certification for quality precision machining.

Supercomputing Services

IFCA has an international level experience in supercomputing techniques: grid distributed computing, parallel computing using MPI, integration with parallel storing systems like GPFS, clusters managing, local area network and 10 Gb WAN use, huge database use ans setup, and virtualization.

On one hand, the installed infrastructure of the IFCA data center contains a cluster with more than 1,500 cores with Infiniband connection and a high performance storing system with more than 900 Tb, with its own full-custom software that allows interactive supercomputing.

On the other hand, IFCA has an outstanding participation in the most relevant national and international initiatives in this field. The integration of the IFCA in the Spanish Supercomputing Network and in the European Grid Infrastructure grants access to a great amount of available resources for applications ranging from supercomputers to big interconnected cluster networks.

But our biggest asset is the IFCA team that works in this knowledge area. It is composed by senior researchers with experience in consultancy and project management and by outstanding junior staff with a deep knowledge in system management and in software development and integration. This team habitually collaborates in projects with international reference centers and also participates in local, nationaland european projects supporting national companies, especially SMEs.

Metrology Laboratory

The laboratory has a surface area of 120 square meters and it is thermally and structurally isolated froma the building to be able to perform highly accurate and precise measurements. It is equiped with 3 sub-millimetric machining optical benches reaching a total length of 12 meters. A two Teslas electromanet is available to allow magnetic field susceptibility characterization. Apart from these devices a complete set of metrology instruments as micrometers, measures, temperature and humidity probes, and calibration standards are also available.

The laboratory has since 2008 the ISO 9001 quality certificate for parts dimensional checking and for dimensional instrumentation calibration.

Clean Room

This facility, commonly used in microelectronics manufacturing and or scientific research, is able to maintain a low level of environmental pollutants like dust.

The room has a surface area of 30 square meters and it is pressurized at +30 Pa. It has an access room of 6 square meters pressurized at +15 Pa. According to ISO 14644, the cleanroom is class 5.5 and the access room is class 8.

The air-conditioning gives a constant flow of 4,700 cubic meters per hour, temperature variation between 18 and 25 ºC and relative humidity between 50% and 70%.

The closure is made by phenolic resin and the floor is made with antistatic PVC electrically grounded. A number of particles real-time display assures continuous monitoring of air quality.

Thermal Chamber

his facility is a DYCOMETAL -70/180 chamber able to perform temperature tests of devices and materials. It can do steady-state stability testing, basic temperature cycling and accelerated stress testing of materials, electronic devices or any other object with a behaviour dependence on temperature or on temperature variations. All test can be fully automated..

The basic features of this chamber are:

Usable volume: 180 liters. Temperature can be regulated from -70 to +100 °C with less than ± 1 °C of internal temperature inhomogeneity.

Temperature regulation accuracy of ± 0.1 °C.

Temperature gradient up to 1 °C/minute when cooling and up to 2 °C/minute when warming.

Interior light, fog-free viewing window, samples holder and lateral port for ease cable routing.

Optical Communications Laboratory

This laboratory is used to research in semiconductor laser based optical communication systems. It has instruments to perform time and spectrum characterization of light sources and passive optical components. It is also equiped with pulse and data frame generator with error detection which allow light sources modulation and transmission channel testing at high bitrates (up to 12.5 Gb/s).

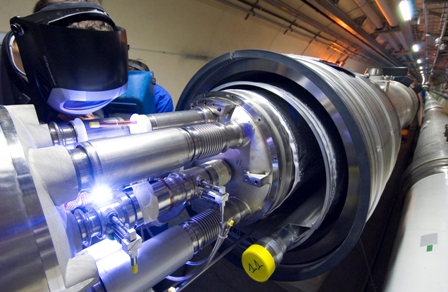

Mechanical Workshop

In the prototyping workshop high precison parts are produced by substractive machining (material removing). In order to do that work a CNC milling machine and a turning machine are available. Apart from that, a shear and a folder are also available for sheet works.

CNC milling machine. This facility allows making small precise pieces. We have experience in making components for opto-mechanics, detection prototypes, laboratory assemblies and large particles detectors. We currently have two machines:

- CONCEPT MILL 300 model, manufactured by EMCO.

- SMC5 model, manufactured by HARTFORD. ERDF funding.

CNC turning machine model Compact Turn 52 manufactured by XYZ. This facility allows producing turning parts with high precision. It is used to perform laboratory tests and for producing pieces for large particles detectors and for astronomical grade instrumentation.